Pre-Press

SP Hi-Tech Printers offer seamless Pre-Press services from high-end proofing to plate making, ensuring adherence to international standards of quality. It maintains proper data security, latest software, and guarantees premium quality output with accurate specifications.

The company houses a complete software library and color management system that support all the major PC and Mac applications.

Press Offset

The press printing facility at SP Hi-Tech flaunts a convergence of web offset machines that offer flexibility, consistent quality with a minimal turnaround time for execution. Using an inline quality control mechanism, the company measures the print quality on the printing machines to achieve high-end results.

SP Hi-Tech is constantly upgrading to ensure state-of-the-art technologies and environment friendly printing facilities.

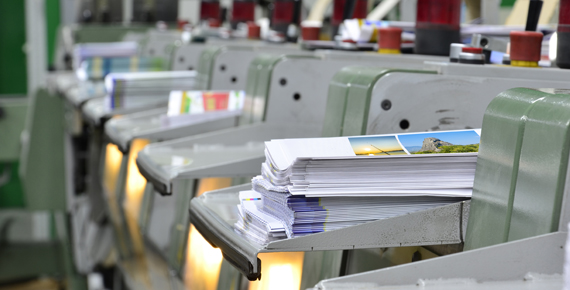

Post Press

The post-printing services encompass a wide range of jobs like - cutting, folding, collating, inserting, sewing, flat, spot, and aqueous UV, thermal gloss and matt lamination, hot foil stamping, embossing, creasing, die-cutting, index cutting, gilding, tipping, silkscreen, et al. All according to the client’s requirements.

Whatever the job at hand, SP Hi-Tech ensures that only the premium quality products leave its premises.

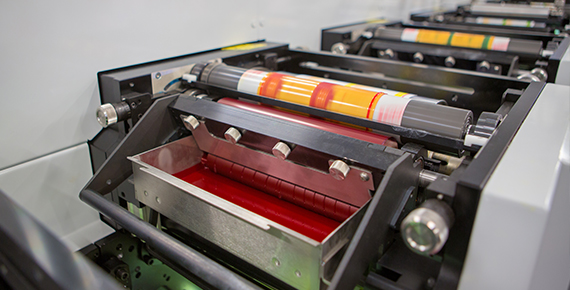

Flexo Press

A Flexo Press uses flexible photopolymer printing plates to imprint images on practically any sort of substrate, including plastic, metallic, film, cellophane, and paper. This printing method is suited for various forms of food packaging. These are entirely customizable in terms of design, colour scheme, and proportions.

SP Hi-Tech provides flawless finished products using Flexo Press.